#PLANT SIMULATION WINDOWS#

The intuitive, context-sensitive ribbon menu user interface of Plant Simulation follows Microsoft Windows standards, making it easy to get familiar and productive quickly. This is achieved through powerful object oriented architecture and modeling capabilities that enable customers to create and maintain highly complex systems, including advanced control mechanisms. Plant Simulation enables companies to create well structured, hierarchical models of production facilities, lines and processes. Source: Siemens Tecnomatix Plant Simulation Modeling Manufacturing Processes

The need to deliver on time and in sequence, introduce lean manufacturing principles, plan and build new sustainable production facilities, and manage global production networks requires objective decision criteria to help management evaluate and compare alternative approaches. In times of increasing cost and time pressures in production along with ongoing globalization, logistics has become a key factor in the success of a company. The simulation tool can be leveraged to analyze global facilities, an entire plant, or simply a few machines in a production line. Using Plant Simulation enables companies to optimize material flow, resource utilization, and logistics for all levels of plant planning.

#PLANT SIMULATION SOFTWARE#

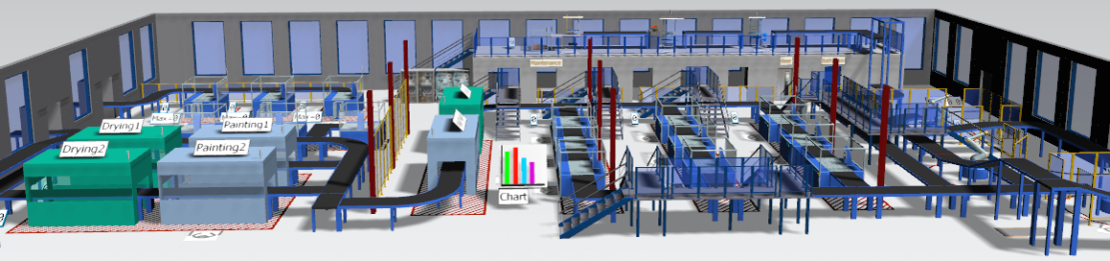

The simulation models can be used as digital twins by integration to the physical product or production, meaning that you can do new experiments and optimisations in the virtual environment with minimum risk at any time.Tecnomatix Plant Simulation software enables the simulation, visualization, analysis and optimization of production systems and logistics processes. We can couple simulation tools with VR, meaning that you can enter the virtual not yet built factory or you can try to work at your future workplace. In the plant simulation models, we can perform experiments with the production system at a low cost and minimum risk, and afterwards analyse performance measurements like capacity utilisations and lead times, as well as locate bottle necks etc.īy process simulation, we can analyse the detailed operation task of the human operators in collaboration with machinery to develop the optimal cell layout, where collision detections are made, the robot programmes are generated and tested directly etc. Computer simulation enables us to simulate the entire plant or a production cell consisting of robots, human operators, feeding systems etc. Here, we work with NX CAD for component/assembly designs, Line designer to design the factory layout. The tools in PLM use Teamcenter as data backbone to integrate software tools and to ensure the workflow from design to operations.īy Mechatronics concept designer, we can design new manufacturing equipment. MCI uses different tools, but the major one is the Siemens PLM (Product Life Cycle Management) software from product design to production planning.

#PLANT SIMULATION PLUS#

A powerful tool for designing or optimising production of logistics facilities is computer simulation (stochastic discrete event plus continuous models) in which a computer model can perform and visualise solutions for detailed analyses and optimisations.

0 kommentar(er)

0 kommentar(er)